Industry’s First Life Cycle Assessment of a Vinyl Record

As a major vinyl record producer, we wanted to gain a deeper understanding of this topic in relation to our core business – pressing records. Our goal is to make informed, well-founded decisions when planning our sustainability initiatives while also contributing to a broader understanding of this issue across the industry.

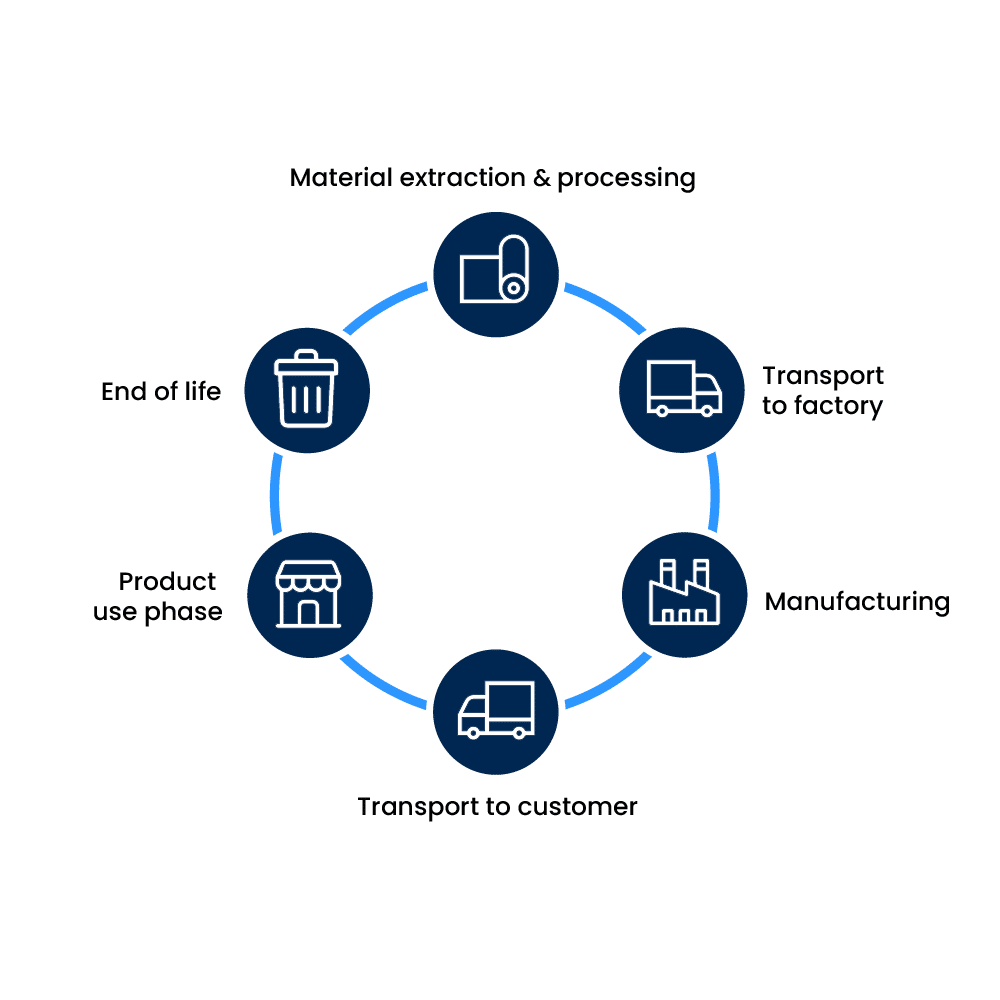

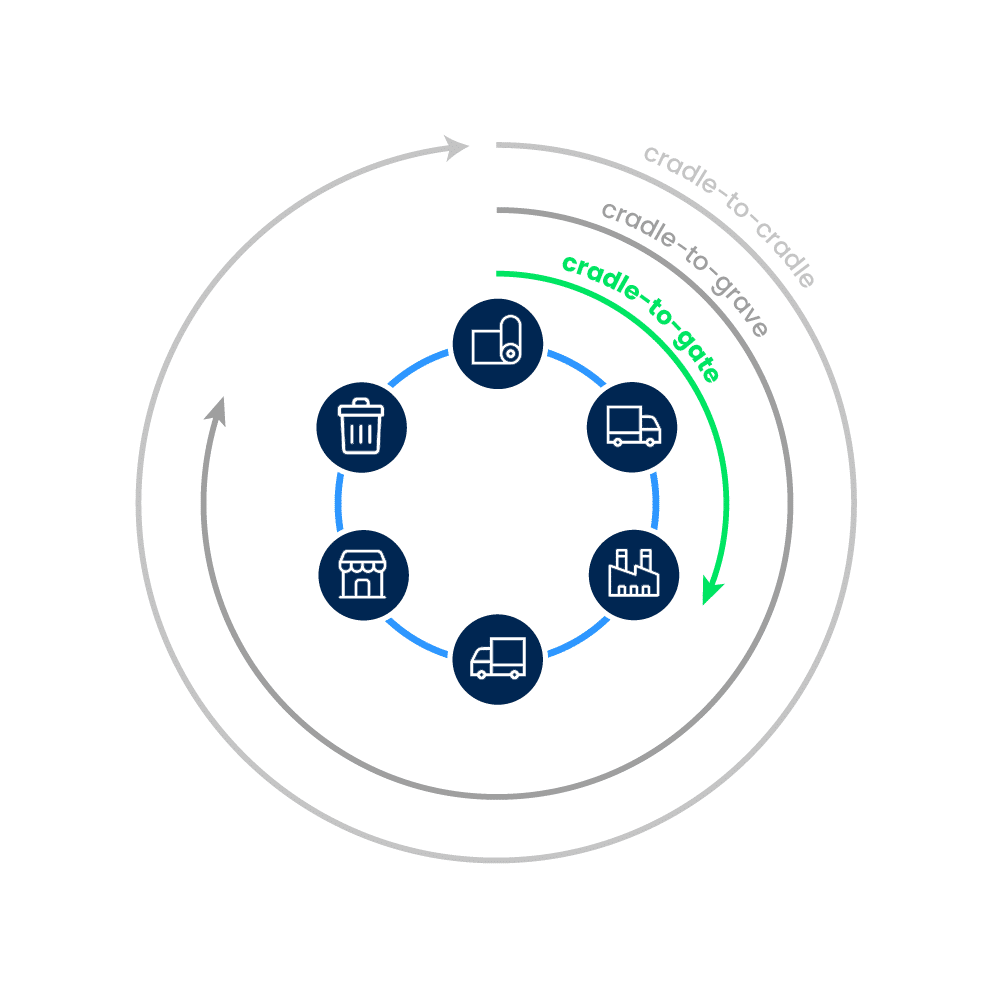

Life Cycle Assessment

To better understand the environmental impact of a vinyl record, we used the Life Cycle Assessment (LCA) methodology, which evaluates the impact of a product throughout its entire life cycle or within a defined scope. We chose to calculate the “cradle-to-gate” phase, covering the process from raw material extraction to the point when vinyl records leave the pressing plant. . Cradle-to-gate phase was chosen for two reasons: (1) it’s the phase we, as a pressing plant, can actually influence; and (2) we lack reliable data for the use phase—how many times a record is played and on what system—as well as for the end-of-life phase (though we like to believe records last for generations 🙂). The assessment was conducted for a standard 140g black vinyl record with a paper inner sleeve, a standard cardboard outer sleeve, and shrink-wrap.

The calculated “cradle-to-gate” phase represents the entire production process of a vinyl record. In our case, the following steps were included in the calculation.

- Pre-Mastering: Preparing the music for cutting.

- Direct Metal Mastering (DMM) cutting: Material and electricity use.

- Galvanization: Use of electricity, water, material, and chemicals.

- Record pressing: Consumption of gas, electricity, water, and raw materials.

- Packaging: Paper inner sleeve, cardboard outer sleeve and shrink wrap

- Material transport: Delivery of all necessary materials to the pressing plant.

- Waste production and disposal: Managing waste throughout the process, including transport to disposal facilities.

- Flue gas emissions: Emissions generated during production.

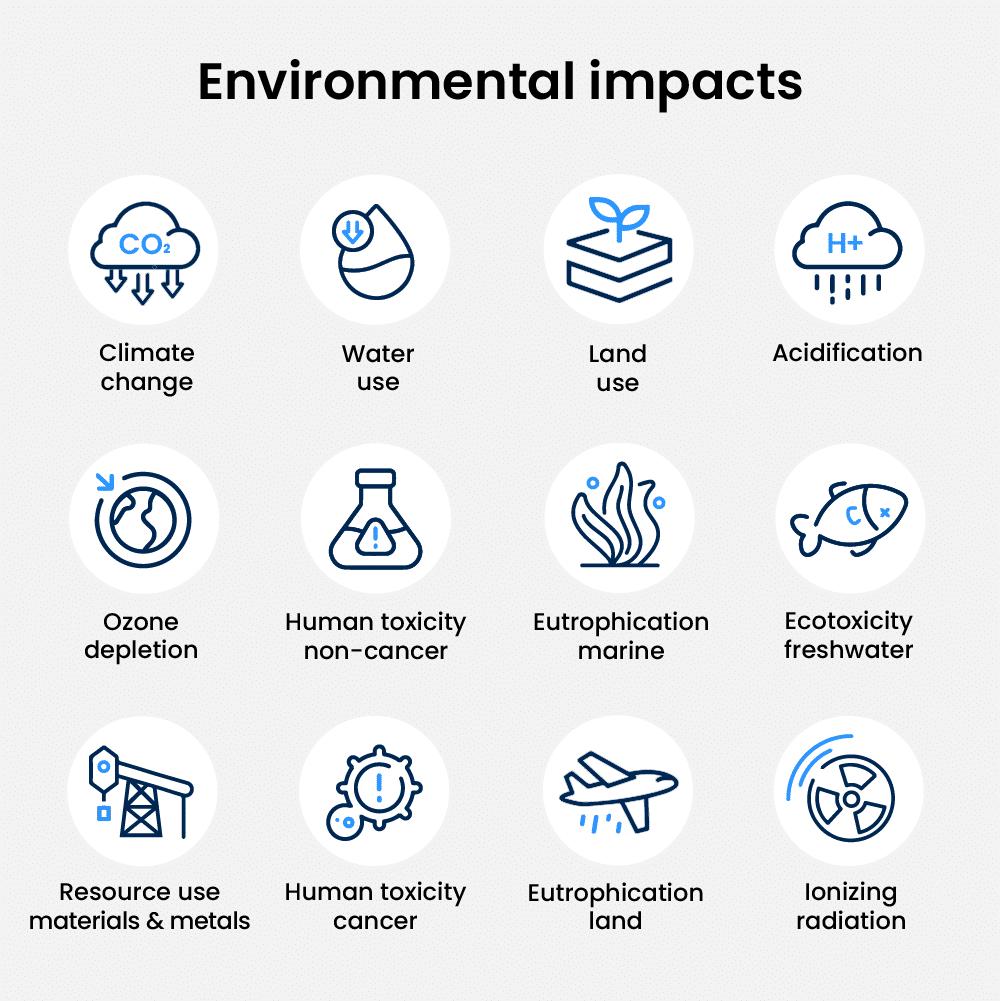

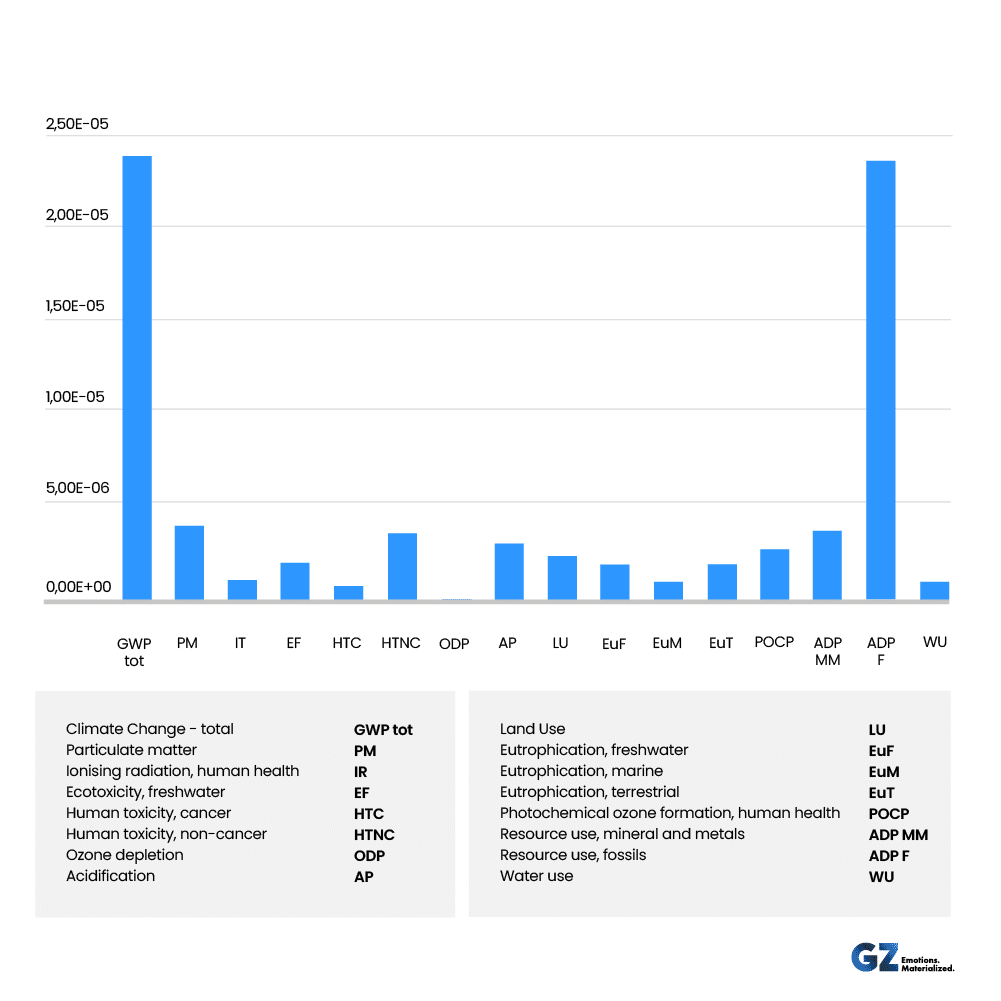

The LCA study evaluates not only the carbon footprint but also other environmental impacts, such as resource depletion, acidification, ozone depletion, or land use. By considering these factors, the method ensures that important environmental aspects beyond CO₂ emissions are not overlooked.

The results can be seen in the graph below. The analysis identified two main impacts – GWP (Global Warming Potential), which corresponds to the CO₂ footprint, and dependency on fossil-based resources (ADP-F).

*The graph is dimensionless, as the presented results represent all examined categories after normalization and weighting. This step converts units from different impact categories into a dimensionless value, enabling comparisons between categories and determining the overall impact.

As the CO₂ footprint proved to be the primary environmental impact to address in the cradle-to-gate phase, we aimed to understand what changes a pressing plant could implement in vinyl record production and how these changes would contribute to environmental impact reduction.

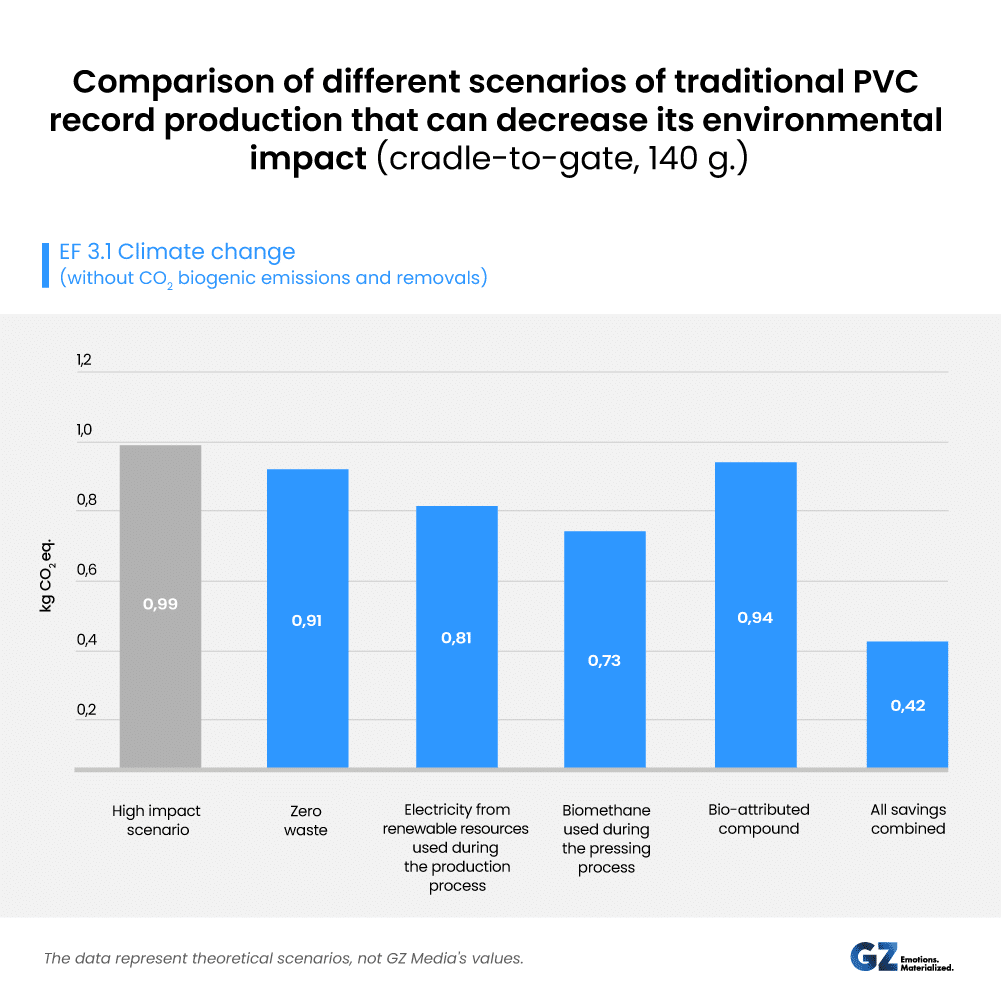

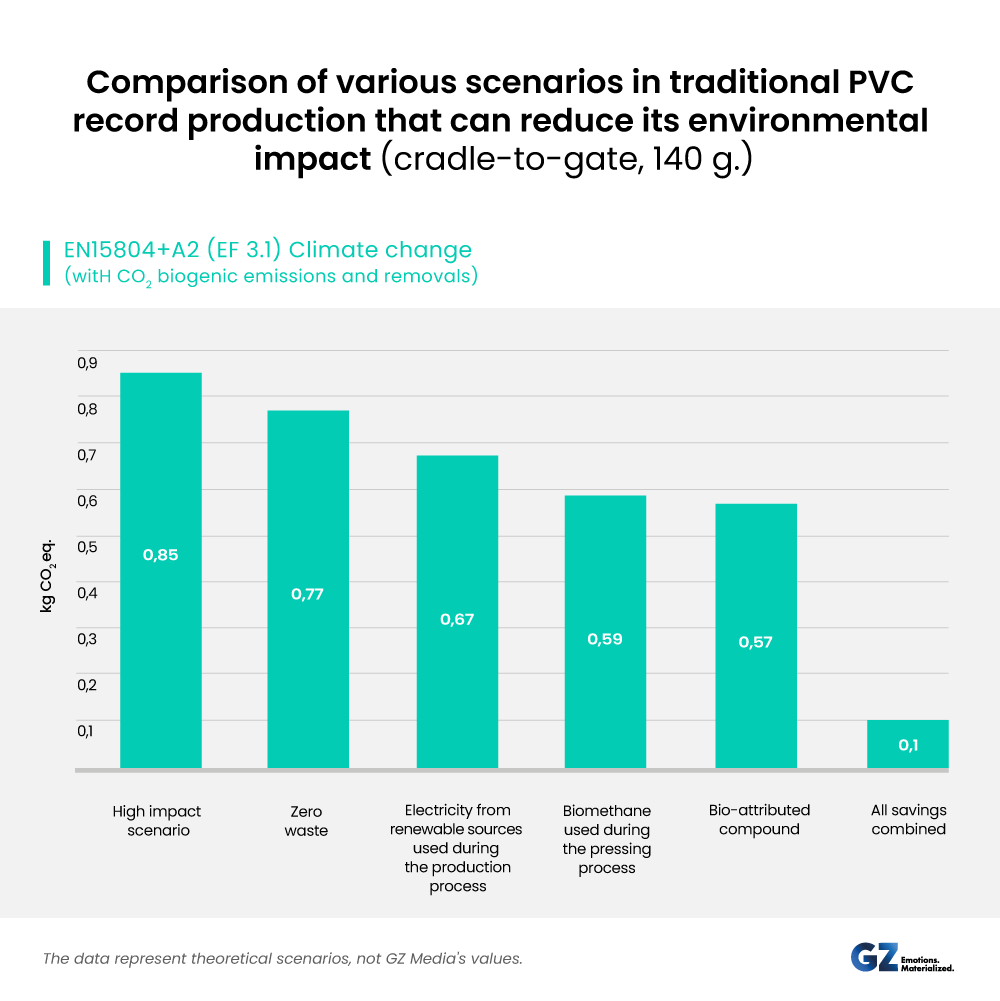

To do this, we defined a baseline “high impact” production scenario representing the most carbon-intensive production conditions and compared it with various alternative options:

• High impact scenario: This scenario is used as a baseline for comparison. It assumes a 10% production waste rate, reliance on fossil-based energy sources, and the use of PVC supplied by a producer with a high carbon footprint.

• “Zero waste” production: Assesses the impact of minimizing waste during production.

• Renewable energy: Evaluates the effects of replacing fossil-based electricity with renewable energy for the production phase.

• Biomethane use: Examines the impact of replacing natural gas with biomethane for the pressing phase.

• Bio-attributed PVC: Evaluates the use of a bio-attributed compound instead of conventional PVC.

From the results, we can see that the CO₂ footprint of a 140g PVC record — if produced solely from fossil-based resources, with 10% production waste and using PVC produced with high CO2 footprint — can be up to 0.99 kg CO₂e. The most significant reduction in carbon footprint would come from using biomethane instead of conventional gas during the pressing phase, followed by switching to electricity from renewable sources. Additionally, reducing production waste contributes to lower emissions by conserving both materials and energy.

Biogenic Carbon and Why Different Methodologies Yield Different Results

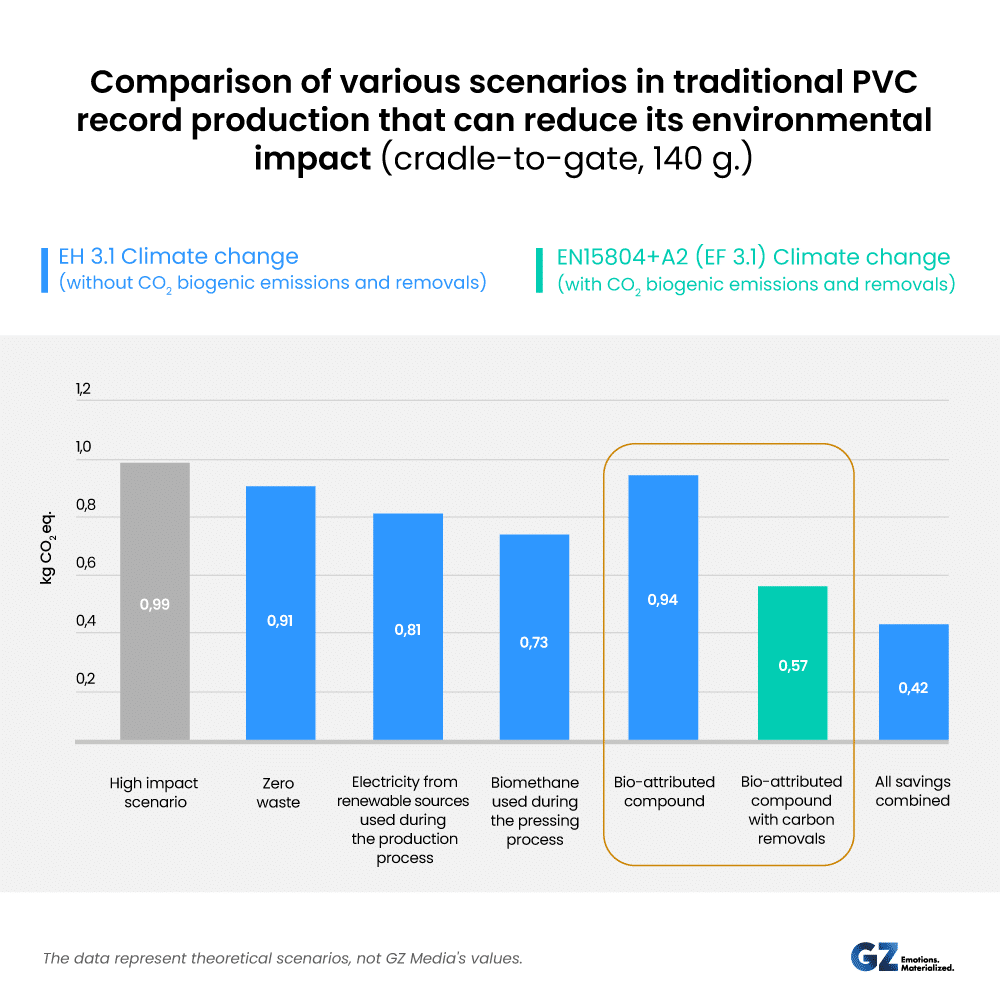

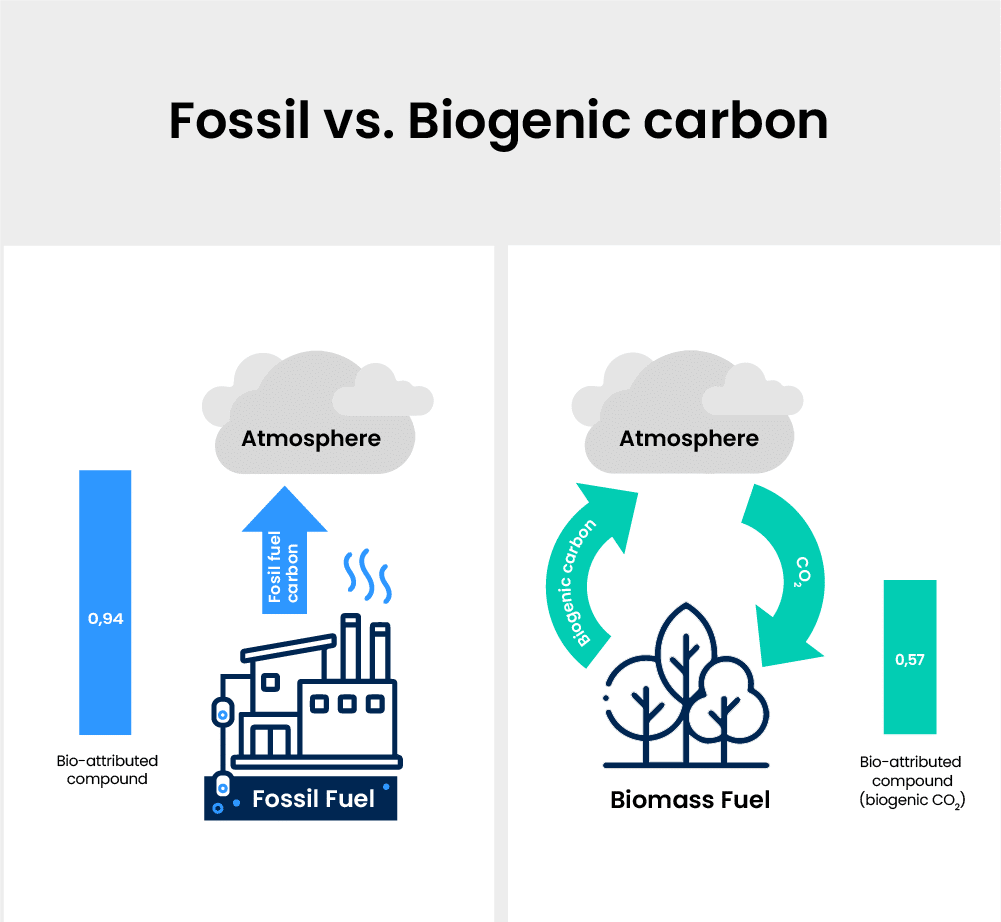

There are two major approaches to calculating CO₂e emissions, which differ in their consideration of biogenic emissions and CO₂ removals. One approach includes them, while the other does not (see the info box for more details on biogenic emissions). The main methodologies that define these approaches are EF 3.1, which does not account for biogenic CO₂, and EN 15804+A2, which does. Currently, biogenic CO₂ accounting is not harmonized, and there is no scientific consensus on whether it should be considered. For this reason, the Greenhouse Gas Protocol requires these figures to be reported separately.

The graph below illustrates the environmental impact reduction of a bio-attributed compound using both methodologies (see more info on bio-attributed compound in our article here).

Biogenic carbon is also present in biomethane and cardboard/paper packaging. If a methodology that accounts for biogenic CO₂ emissions and removals is used, the results would be as follows.

All of the scenarios mentioned above can be combined and implemented either fully or partially. However, their feasibility depends on economic factors, such as the premium cost of renewable energy and bio-attributed compounds, as well as technical limitations— for example, achieving absolute zero waste may not be possible, but it can be minimized to the lowest achievable levels through improved efficiency and recycling efforts.

More Information on the Study

The Life Cycle Assessment (LCA) was conducted by the external company LCA Studio, led by Prof. Vladimír Kočí, an international EPD verifier. The assessment follows the standardized Life Cycle Assessment methodology in accordance with ISO 14040 and ISO 14044. The Life Cycle Impact Assessment (LCIA) methodology used is Environmental Footprint 3.1. Whenever possible, primary data from production or suppliers were used; when unavailable, data from LCA databases were utilized. The analysis was performed using LCA for Experts software, along with data from the Sphera and Ecoinvent databases.

This study was conducted for internal purposes of GZ Media and reflects the specific conditions and methodologies at the time of its development. While we share these findings to contribute to broader industry discussions, the data and insights should not be interpreted as definitive claims or an endorsement of a single perspective. We encourage further exploration and welcome diverse viewpoints on the topics presented. This study was published in December 2024, this article was updated in August 2025.

Limitations of the Study

Data from suppliers may vary in format, scope and methodology, making direct comparisons challenging. Additionally, different LCA databases can yield varying results even when using similar input data. The findings are geographically and technologically relevant but may not be applicable in other contexts. Furthermore, LCA does not account for certain important environmental aspects, such as microplastics production.