Bio-attributed Compound: Facts and Myths

Bio-attributed compound

A bio-attributed compound is produced using ethylene from second-generation bio-based feedstock (e.g., used cooking oil) instead of fossil raw materials. For this reason, it has a lower carbon footprint compared to conventional PVC. Production is based on mass balance principle, and the concept is monitored and certified by ISCC PLUS.

How does it work? What is mass balance?

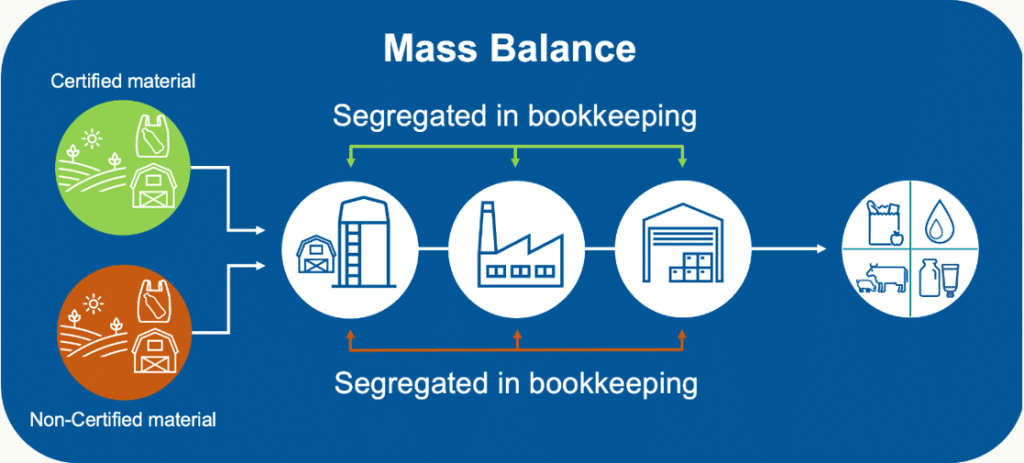

The ISCC PLUS mass balance approach ensures that the amount of sustainable material entering a production process equals the amount exiting. This method allows for mixing with non-sustainable material while maintaining accurate records. The mass balance approach requires precise bookkeeping. Companies must document the amount of sustainable material entering and leaving each stage of production to ensure that the sustainable output matches the sustainable input.

Unlike systems that require sustainable and non-sustainable materials to be kept separate, mass balance allows them to be mixed during manufacturing. This is because current technologies and infrastructure do not make it possible to keep the flows separate. It can be compared to purchasing renewable energy – a customer who orders renewable electricity does not receive “different” electricity from the socket. Instead, the balance is maintained solely through accounting, ensuring that the amount of renewable electricity sold corresponds to the amount fed into the grid.

Source: ISCC PLUS

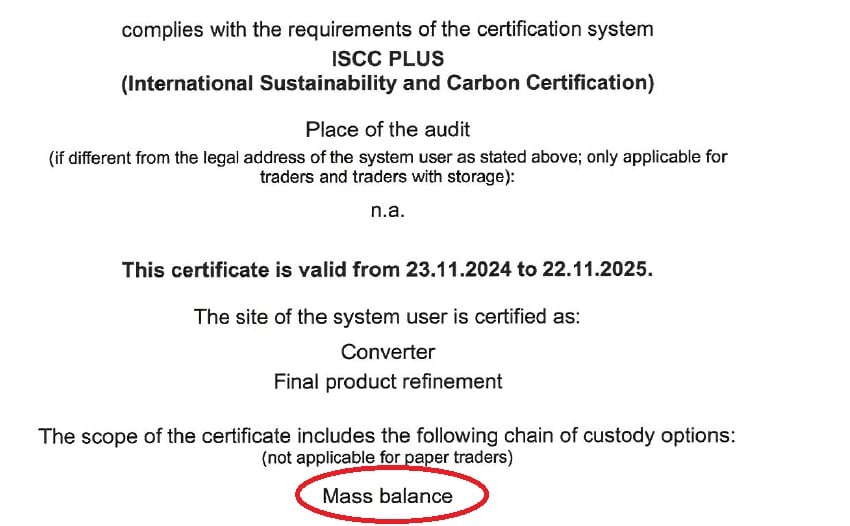

The ISCC PLUS certification, based on the mass balance approach, ensures that the sustainable content in bio-attributed compounds is accurately tracked throughout the supply chain. Companies within the supply chain undergo regular audits to verify compliance with ISCC PLUS mass balance requirements.

How can I check what my supplier offers?

Every part of the value chain (e.g., ethylene supplier, PVC producer, pressing plant) must be ISCC PLUS certified. These certifications are publicly available in the ISCC PLUS database, where anyone can verify the product a company offers. If the certificate states “mass balance,” all the principles mentioned above apply. To our knowledge, all major PVC and copolymer producers in Europe offer bio-attributed compounds based on the same principle.

Sustainability benefits

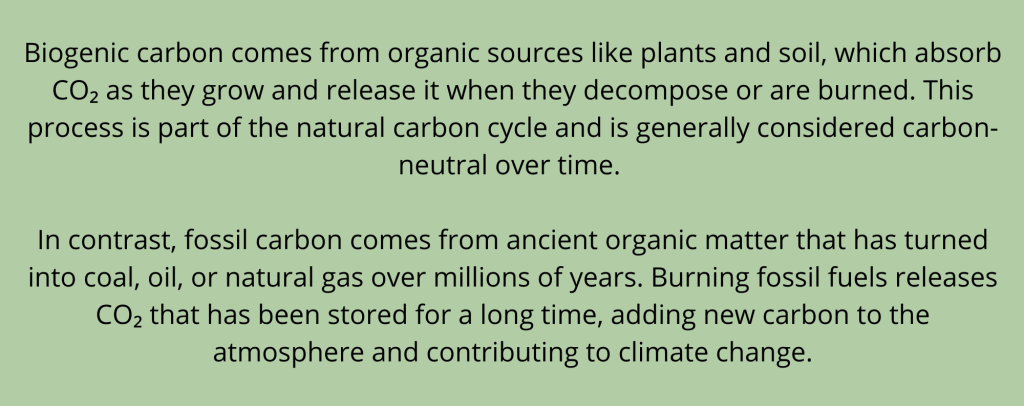

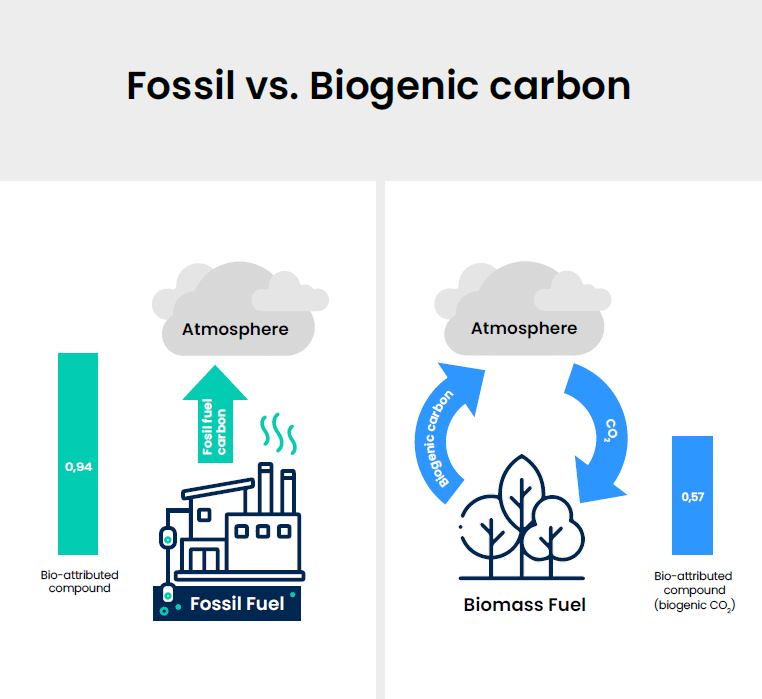

The calculated CO₂ footprint reduction of a bio-attributed compound is approximately 90% compared to a regular PVC compound. This reduction is based on biogenic removals, which must be reported separately under the Greenhouse Gas Protocol. This is because there is no scientific consensus on whether and how biogenic removals should be accounted for.

If the CO₂ reduction of a bio-attributed compound is applied to a 140 g vinyl record (see more on the topic in article here) , the estimated savings are as stated below. The actual reduction may vary depending on the compound supplier and the pressing plant producing the records:

• 4% – 6% CO₂ reduction without carbon removals

• 42% – 45% CO₂ reduction when including carbon removals

The sustainability benefit of switching to a bio-attributed compound lies in reducing the use of fossil-based resources and contributing to increased demand for the resources, thereby supporting the expansion of non-fossil-based production.

Can I get a test pressing from biovinyl to compare the quality? No.

This is a question we receive from time to time, and the simple answer is “no.”

Why? Because the entire system operates on the mass balance principle, meaning a company cannot determine whether a specific batch of PVC contains a certain percentage—or any at all—of bio-attributed material. Bio-ethylene is mixed within the system and cannot be individually tracked. As a result, comparing test pressings of “regular” vs. “biovinyl” is not technically possible. Of course, you can order a test pressing in a bio-attributed variant and thus reduce your environmental impact.

MAIN TAKEWAYS

• If bio-attributed PVC (compound) is produced using the mass balance principle, it cannot be physically separated or traced. The amounts are tracked through accounting, ensuring that only the volumes produced with bio-ethylene are sold on the market. Physical separation of the material is not possible.

• The type of material used by a PVC producer or pressing plant can be verified in the publicly available ISCC PLUS database.

• Any claims that bio-attributed material is a “different material” (e.g., that it sounds the same or better than traditional PVC) may be misleading. In practice, a company never knows whether a specific batch contains a certain percentage—or any at all—of bio-attributed material. This also means that comparing test pressings of “regular” vs. “biovinyl” is not technically possible.

• Quantifying environmental savings is complex due to the involvement of biogenic carbon, which must be reported separately. When communicating the reduced environmental impact of a record, the entire product — not just the compound savings — must be taken into account.

If you’re considering this more sustainable material as an option, feel free to reach out — we offer competitive pricing and are happy to discuss the possibilities.